Consider; you buy and install equipment in your business.

Or you are responsible for these things.

The machines are hidden! Either machines are located remotely?

Or machines are located where nobody comes?

Or people in the area got low focus on the expensive machinery?

How can you be sure the machinery continues working?

How can you make sure you and/or the company will not experience loosing unknown amount of money?

How can you build focus on maintenance and enthusiasm in the team?

Do not worry

About Us

ProX3 is a solution to monitor equipment. We deliver monitoring hardware we and you install on your equipment. We deliver a monitor service based on a subscription. Based in the Cloud, our mission is not only to deliver stunning analysis but also foster an enthusiasm in your organisation that cares for equipment.

Our services

Collect vibration from machinery

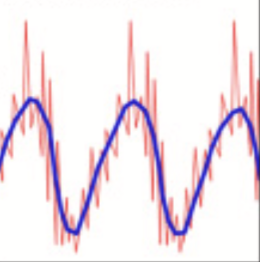

In industrial applications, the measurement and analysis of vibrations play a crucial role in predictive maintenance, machine monitoring, and fault detection. Nodes, refer to measurement sensors that are strategically placed on machinery or structures to capture vibration data. Collecting vibration information from machinery involves a systematic process that ensures accurate, reliable, and actionable data for further analysis.

Nodes are sensors equipped with the capability to detect and measure vibrations. These sensors are accelerometers, velocity sensors, and displacement sensors. This includes measurement of temperature.

Assemble to cloud

Assembling vibration data from many remote nodes into the cloud is a transformative approach that offers unparalleled advantages in industrial monitoring and maintenance. Through continuous data acquisition, secure transmission, centralized cloud storage, and advanced analytics, this method empowers organizations with the insights needed to ensure optimal machine performance and facilitate predictive maintenance. The result is a more efficient, reliable, and cost-effective operation

Deliver results

ProX3 uses the assembled data in the field of predictive maintenance and condition monitoring. By analysing vibration data, ProX3 detects potential issues before they lead to significant problems, thereby improving machine reliability and reducing downtime. Integrated with alerting systems, this analysis ensures timely interventions.

This is how you receive information about machine performance for machines that is one way or the other hidden.

Enthusiasm

ProX3 helps you to build enthusiasm in the production team. ProX3 can send information to more people and help you to gain interest in good maintanence.

What people are saying

Our compressor makes air to all important machines in our company. We knew that it was becoming an older machine located outside in the wildness under a little roof in a place we never visit.

We monitored the compressor with ProX3 for a while. We could see the machine became unstable.

We decided to purchase a new compressor. Thanks to ProX3 we got focus on the importance of our compressor.

Carsten, Dan Thai Machinery“ProX3 saved our company from stand still”

Thailand

Configuration (Pricing)

You can Enable or Disable wanted services at anytime to manage your subscription.

Collect

Node enabled

- Collecting data from machinery

- ProX3 ensures that nodes are firmware upgraded.

Assemble

Network enabled

- Assembling data from nodes

- ProX3 ensures that gateway receives data from nodes

- ProX3 ensures that gateways are firmware upgraded.

- ProX3 deliver node data to your ProX3 cloud account

- ProX3 maintain cloud data history for 5 years.

Deliver

Communication

- ProX3 produces graph’s for vibration data for node

- ProX3 monitor changes and produces alerts.

- ProX3 sends alerts to users.